EPE pearl cotton can be according to the different requirements of customers, made into various shapes. To make pearl cotton shape we will need with the aid of mold. What are the features in the production of pearl cotton extrusion mould? What kind of mold has better durability?

1, high wear resistance, in order to increase the rigidity of the plastic parts and mechanical performance, widely used in plastic formula of glass fiber, inorganic filler to strengthen, after joined these additives, these high speed, with molten material into the mold cavity, the cavity of the mould friction is great, if the mould material wear-resisting, easily make cavity by excessive wear, therefore, make this kind of mould materials especially should have good wear resistance.

2, good thermal conductivity In extrusion molding, good mold temperature control has great influence on the quality of plastic parts, especially in the semi crystalline thermoplastic plastic machining more important. Usually, the copper alloy thermal conductivity is much better than steel, but its lower elastic modulus, hardness and durability. The thermal conductivity of the steel cooling system to compensate for inadequate available.

3, high corrosion resistance, pearl cotton production in the production of raw materials, adding additives, such as flame retardant, not only in this way, the chemistry of plastic and additive itself has the nature of the corrosion. When plastic raw material containing additive, abrasive, together into the mold cavity, if there is no corrosion resistance, mold mold will be very easy to damage, therefore, it is best to use corrosion resistant steel, or to the mold surface treatment, electroplating chromium plated or nickel plated.

4, polishing performance is good High demand for mold cavity wall, the roughness is very small, so as to adapt to the requirement, good gloss on the surface of the plastic to the mold cavity generally must carry on the polishing processing, surface as light as possible, therefore, request mould material is easy to polish, chooses the material should not have impurities and defects such as porosity.

5, good dimensional stability of extrusion die in the forming operation, the temperature of the mold cavity to achieve above 300 ℃, is easy to produce micro cavity structure changes, resulting in the mold size change, make the plastic parts size is not stable, therefore, can choose suitable tool steel tempering treatment, the heat treatment of steel. In order to improve the hardness and wear resistance, the general mould to heat treatment. But should make the minimum heat treatment effect on the size of the mould, can be used to ba cutting machining of hardened steel, the steel without heat treatment after machining.

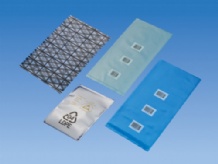

PE bag of metal

PE bag of metal Pearl cotton and bubble film

Pearl cotton and bubble film Pearl cotton PE anti-static bag..

Pearl cotton PE anti-static bag.. Kraft paper composite bubble ba..

Kraft paper composite bubble ba.. Bubble bag

Bubble bag EPE pearl cotton

EPE pearl cotton