Polyethylene plastic formability

source:Dong guan jianxing packing production co.,ltdUpdate time:2014-12-30Click on the:1035time

Small crystal material, moisture absorption, need not to fully dry, good liquidity, liquidity is sensitive to pressure and molding time with high-pressure injection, uniform temperature, filling speed, pressure maintaining full. Should not be in direct gate, to prevent uneven contraction, the internal stress increased. Pay attention to choose the gate location, to prevent shrinkage and distortion.

2. Scope and contraction value is big, obvious directivity, easy to deformed. Cooling speed should be slow, mold slag hole, and the cooling system.

3. The heating time shoulds not be too long, otherwise it will decompose, burns.

4. Soft plastic parts have shallow lateral recess, forced demoulding.

5. Melting body fracture may occur, unfavorable contact with organic solvent, to prevent cracking.

The high pressure low density polyethylene (LDPE), high density polyethylene (HDPE) and linear low density polyethylene (LLDPE). Film is its main processing products, followed by sheet and coating, hollow containers such as bottles, cans, barrels and other all kinds of injection molding and blow molding products, pipes and wire, cable insulation and sheath, etc. Mainly used in packaging, agriculture and transportation department.

Commercial high density polyethylene (HDPE), 0.945 ~ 0.96 g/cm3 density, melting point of 125 ~ 137 ℃.

Linear low density PE (LLDPE), 0.925 g/cm3 density, melting point of 120 ~ 125 ℃.

High pressure low density PE (HP - LDPE), 0.918 g/cm3 density, melting point of 105 ~ 115 ℃.

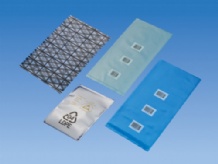

PE bag of metal

PE bag of metal Pearl cotton and bubble film

Pearl cotton and bubble film Pearl cotton PE anti-static bag..

Pearl cotton PE anti-static bag.. Kraft paper composite bubble ba..

Kraft paper composite bubble ba.. Bubble bag

Bubble bag EPE pearl cotton

EPE pearl cotton