Soft package industry gravure new way out

source:Dong guan jianxing packing production co.,ltdUpdate time:2014-12-30Click on the:1027time

In recent years, an increasing competitive pressure, flexible packaging gravure industry (raw material) and the upstream industry and downstream enterprise (client), the influence of the living space of flexible packaging gravure enterprises continuously squeezed. In this grim situation, more and more flexible packaging gravure enterprises have begun to realize that the enterprise must be real effort to understand the real demand for soft packaging, packaging must be carried out in the structure adjustment, must carry out transformation and upgrading, to have room for improvement. And under the background of green environmental protection, flexible packaging gravure enterprises from traditional processors to overall solution provider, but also the historical opportunity of flexible packaging gravure industry faces. And flexible packaging gravure industry of new technologies, new processes, new equipment and new materials will be toward the green environmental protection, energy conservation and emissions reduction, reduce loss, improve the quality and efficiency in the direction of rapid development. In this context, no benzene technology, loss control, efficient drying device, solvent recovery and a series of new technologies applied to the flexible packaging gravure industry.

Today, advanced gravure press auxiliary operation time shortened significantly. On the edition, inking integration car implemented on version, edition, inking integration operation, can the offline version of roller and ink tank cleaning; Through rapid inking system, directly into the ink solvents from room plate, into the amount directly by the ink viscosity control instrument control; Without tooling replacement sleeve roller technology, labor intensity is reduced, replacing time shorten; Rapid change the squeegee technology to realize the rapid replacement of scraper; Laser on the edge system, safety chuck fast clamping system has realized the rapid fluctuate; The fault display and alarm help maintenance personnel rapid diagnosis and maintenance; Historical fault alarm indicator can reduce the time of the maintenance personnel some troubleshooting.

Intaglio printing process in the drying oven energy accounted for a larger proportion, heat pump technology, the application of waste heat recovery system, a hierarchical oven effectively reduce the consumption of heat energy. Dry automatic monitoring system based on LEL in energy conservation and emissions reduction at the same time, also can prevent dry system the risk of explosion, burning, and significantly reduce the cost of tail gas treatment.

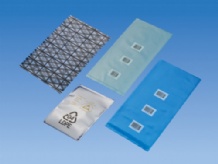

PE bag of metal

PE bag of metal Pearl cotton and bubble film

Pearl cotton and bubble film Pearl cotton PE anti-static bag..

Pearl cotton PE anti-static bag.. Kraft paper composite bubble ba..

Kraft paper composite bubble ba.. Bubble bag

Bubble bag EPE pearl cotton

EPE pearl cotton