Outstanding features of compound packing materials

source:Dong guan jianxing packing production co.,ltdUpdate time:2014-12-30Click on the:1332time

(1) pressure sensitive resistance: post-it note is pressure sensitive resistance composite packaging materials, in addition to make stickers, labels, also can cover tape, transfer printing, wall material, etc. It is different from ordinary plastic performance, first of all, in a wide temperature range, with a small pressure of pressure and a short period of time show good adhesion ability; Second, can happen with a variety of different surface adhesion; Third, the ability to maintain contact with the surface for long, and not easy to aging.

(2) oil resistance: used for food packaging materials often opaque oil as one of the basic requirements. In order to prevent the penetration of oil and grease on the porous structure of paper, sometimes need to clogging pores with film-forming substances, and it is best to use oil and fat is not chemical affinity. This means that has better effect to use polar polymer, make it has good resistance to oil and grease. The polar polymer including carboxymethyl cellulose (CMC), ethyl cellulose (EC), methyl cellulose (MC) and poly (vinyl alcohol) (PVA), styrene - maleic anhydride copolymer (SMAC), etc.

(3) heat sealing: some packaging requirements fast heat sealing, so for this kind of composite packaging material chooses heat sealing coating should have higher requirements. In normal conditions, it must be with thermoplastic and adhesive. Under the condition of heating pressure, it must become a strong adhesiveness. Even before the heat sealing zone, cooling zone remains strong. There are many types of heat sealing coating polymer, solvent such as ethyl cellulose and acrylic acid, ethylene, polyvinylidene chloride copolymer and poly (vinyl acetate, etc. Or by their mixture was prepared with wax, the heat sealing temperature range is 100 ~ 180 ℃; Water-based sex such as polyvinyl chloride (PVC) and polyethylene vinyl acetate, heat sealing temperature range is 82 ~ 163 ℃.

(4) the barrier property: many food packaging materials have certain anti oxygen performance, so as to prevent deterioration. At the same time, to keep the bag smell is related to its gas shielding ability. The characteristics of compound packing materials (i.e., shielding ability) usually expressed using oxygen permeability coefficient. So-called oxygen permeability coefficient (P), is under the standard pressure and temperature, per square centimeter area, every second, every cm hg pressure through the thickness of 1 cm thin film of gas volume (cubic centimeters). Generally speaking, a component of composite packaging materials can indirectly reflect the size of the shielding ability. For example, low density polyethylene (P = 2.8; High and low density polyethylene (P = 0.4; Polypropylene (P = 2.3; Polyvinylidene chloride (P = 0.005. The difference between them is very big, so must pay attention on the material of the component.

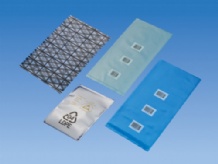

PE bag of metal

PE bag of metal Pearl cotton and bubble film

Pearl cotton and bubble film Pearl cotton PE anti-static bag..

Pearl cotton PE anti-static bag.. Kraft paper composite bubble ba..

Kraft paper composite bubble ba.. Bubble bag

Bubble bag EPE pearl cotton

EPE pearl cotton