The physical and chemical process of foam packing materials

source:Dong guan jianxing packing production co.,ltdUpdate time:2014-12-30Click on the:1197time

Physical:

Often used the low boiling point hydrocarbon or halogenated hydrocarbons into plastic, plastic softening when heated, at the same time into the liquid volatilization expansion foam. Such as: polystyrene foamed plastic, can be in styrene suspension polymerization, the pentane first dissolve in monomer, or under the heat pressure is aggregated into bead of polystyrene resin treated with pentane, made a so-called foamed polystyrene beads. The bead pretest to soak in the hot water or steam, then placed in the mold zhongtong into steam, and make the pretest bubble particle secondary expansion and sinter with each other, after cooling and mold cavity shape of the same products. They are widely used for insulation and shockproof materials in the packaging.

Chemical method:

Can be divided into two categories: one is to use chemical foaming agent, they are heated at the liberation of the gas. The commonly used chemical foaming agent, such as azobisformamide, azodiisobutyronitrile, N, N '- two nitroso five four methylene amine, sodium bicarbonate, etc. A lot of thermoplastics are available this method into foam. Such as: PVC foam shoes, is made of resin, plasticizer, foaming agent and other additives, the batch in the injection moulding machine, decomposition of foaming agent in the barrel, the material in the mold in the foam.

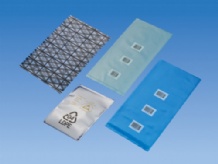

PE bag of metal

PE bag of metal Pearl cotton and bubble film

Pearl cotton and bubble film Pearl cotton PE anti-static bag..

Pearl cotton PE anti-static bag.. Kraft paper composite bubble ba..

Kraft paper composite bubble ba.. Bubble bag

Bubble bag EPE pearl cotton

EPE pearl cotton