EPE pearl cotton foam purpose and process

source:Dong guan jianxing packing production co.,ltdUpdate time:2014-12-31Click on the:1279time

EPE foam cloth production line, the use of advanced single butane physical foaming technology, products high foaming rate and energy saving efficiency. Production line adopts the explosion-proof electrical components, frequency control of motor speed and intelligent digital display instrument automatic control, smooth operation safety, convenient operation, stable and reliable quality, can be continuous in the production of various specifications of EPE foam sheet. Replace the head mould, also can produce foamed pipe, foaming and foam screen.

2. Process

Plastic particles to formulation and mixing heating extrusion, foaming agent injection to mixing and plasticizing extruder, cooling molding - sizing cutting cutting - cooling traction to flattening, winding and finished products

First mixing materials such as polyethylene, into the extruder hopper, after large length to diameter ratio of extruder melt mixing, while in the middle of extruder high-pressure injection foaming gas and molten monoglycerides, and has molten plastic mixing, mixing of the nose, mouth die extrusion forming, after cooling, traction, flattening, winding foamed sheet (film) products.

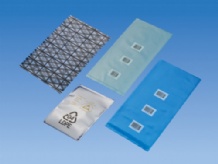

PE bag of metal

PE bag of metal Pearl cotton and bubble film

Pearl cotton and bubble film Pearl cotton PE anti-static bag..

Pearl cotton PE anti-static bag.. Kraft paper composite bubble ba..

Kraft paper composite bubble ba.. Bubble bag

Bubble bag EPE pearl cotton

EPE pearl cotton